Technology

11 min read

Innospace Achieves Free 3D Printing of Titanium Aerospace Components

3D Printing Industry

January 21, 2026•1 day ago

AI-Generated SummaryAuto-generated

Innospace has successfully 3D printed a spherical titanium aerospace pressure vessel without internal supports using a proprietary low-overhang method and standard laser beam powder bed fusion. This achievement, enabled by Oqton's 3DXpert software, demonstrates the feasibility of manufacturing complex aerospace components with reduced traditional limitations. The technology allows for scalable parametric pressure vessels for space applications.

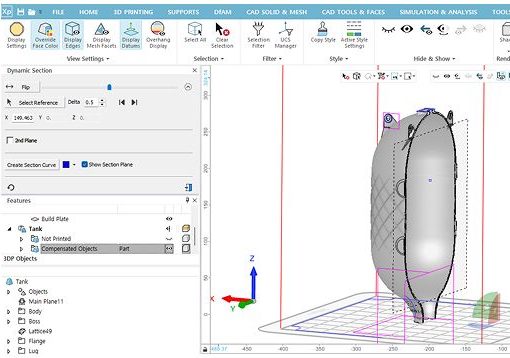

South Korea–based aerospace and defense company Innospace has produced a spherical titanium pressure vessel without internal supports using its proprietary low-overhang 3D printing method. The dome was fabricated with Ti-6Al-4V Grade 23 and designed, simulated, and built using Oqton’s 3DXpert software on a standard Laser Beam Powder Bed Fusion system, showing the feasibility of manufacturing complex geometries in aerospace components without specialized hardware or support structures.

“With 3DXpert, Innospace turned a complex concept into real, reliable, aerospace-quality components, printed on standard PBF-LB machines. We’re proud to empower our partners to take additive manufacturing to new levels of performance and reliability,” stated Oqton.

Overcoming Traditional Additive Manufacturing Limits

Creating dome- or sphere-shaped components via conventional additive manufacturing typically requires specialized machines, custom hardware, or advanced hatching strategies. Innospace, however, completed the print on a standard Laser Beam Powder Bed Fusion (PBF-LB) system, demonstrating the accessibility and efficiency of their approach.

This achievement opens the door to the company’s next-generation products: parametric pressure vessels for space applications, ranging from 1 to 15 liters in capacity, which can be scaled as needed. “This is what AM as a product means to us,” said Jo Intaek, Director of Innospace’s Advanced Manufacturing Business Division. “Technology you can trust, delivered at rocket speed with aerospace quality.” The technology is applicable for both fuel and oxidizer tanks.

Complex Aerospace Parts Made Possible with Advanced 3D Printing Innospace’s recent success with support-free 3D printed titanium pressure vessels highlights a broader trend in aerospace additive manufacturing: companies are increasingly using software-driven workflows and advanced printing strategies to produce complex, high-performance components efficiently and reliably.

For instance, Hexagon introduced its Advanced Compensation technology, designed to address one of additive manufacturing’s biggest challenges: producing large, intricate, and high-precision metal components in a single build. By combining process simulation with 3D scan compensation, the software predicts and corrects distortions and shrinkage, ensuring parts match their intended geometry. Additive Industries demonstrated the system by printing a stainless-steel jet engine exhaust mixer with ±0.2 mm tolerance on the first attempt, reducing material waste and support structures.

Similarly, 3D Systems, in collaboration with NASA and partner universities, uses Direct Metal Printing (DMP) and Oqton’s 3DXpert software to produce high-performance spacecraft thermal management systems, including titanium and nickel-titanium radiators and heat pipes. By embedding functional structures like shape-memory alloy actuators directly into the parts, the team reduces weight, assembly complexity, and manufacturing steps, resulting in flight-ready, lightweight, and efficient components.

The 3D Printing Industry Awards are back. Make your nominations now.

Do you operate a 3D printing start-up? Reach readers, potential investors, and customers with the 3D Printing Industry Start-up of Year competition.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us onLinkedin.

Featured image shows Spherical titanium pressure vessel without internal supports. Photo via Innospace.

Rate this article

Login to rate this article

Comments

Please login to comment

No comments yet. Be the first to comment!