Space & Astronomy

8 min read

Revolutionary AI Hyperspectral Camera Set to Transform Food Industry

FoodProcessing.com.au

January 21, 2026•1 day ago

AI-Generated SummaryAuto-generated

Scientists are developing an AI-powered, compact hyperspectral camera for real-time material and quality analysis. This camera uses a spectrometer and AI to identify invisible chemical properties in food, textiles, and plastics. The intelligent approach analyzes only relevant areas, reducing data and energy consumption. This technology will improve food quality control, textile sorting, counterfeit detection, and agricultural assessments, leading to more sustainable and efficient processes.

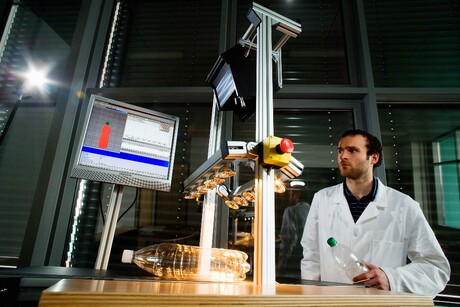

The OASYS project focuses on optoelectronic sensors for application-oriented systems. In the subproject A1, a team of scientists and industry experts is developing an ultra-compact, energy-efficient hyperspectral camera that uses artificial intelligence to perform complex material and quality analyses in real time. The integrated spectrometer records spectral characteristics, revealing chemical properties that are invisible to the human eye. This enables defects in food or the composition of textiles or plastics to be identified quickly and accurately.

The novel hyperspectral camera offers wide-ranging applications in industrial and agricultural processes. Its innovative approach combines conventional 2D imaging with artificial intelligence and spectral analysis. A standard 2D camera first captures a high-resolution image of the target object. Artificial intelligence then analyses the image in real time, automatically identifying regions of interest. The integrated spectrometer subsequently performs spectral analysis exclusively at these selected positions, determining the chemical composition. This intelligent approach enhances the efficiency of hyperspectral measurements. Rather than capturing spectral data across the entire image — a computationally intensive process — the system analyses only the relevant measurement points. This targeted method reduces data volumes, energy consumption and processing time.

The information obtained in this way supports, for example, the reliable sorting of textiles and plastics. It also increases the reliability of identifying counterfeit products. Additionally, it improves quality control in food processing by detecting pressure marks and defects, and enables an accurate assessment of plant condition and nutrient requirements in agriculture. Automated evaluation enables faster and more reliable decision-making. At the same time, processes become more sustainable, and economic resources are used more efficiently.

“With the compact hyperspectral camera from OASYS A1, we are developing technology that can be used directly in production lines, sorting facilities, or in the field for analytical processes,” explains Heinrich Engelke, project manager at the Fraunhofer Institute for Photonic Microsystems IPMS. “The combination of miniaturisation, energy efficiency and artificial intelligence opens up completely new applications, while also making an important contribution to resource conservation and process reliability.”

The components developed in the project will form the basis for future sensor systems that could improve industry, recycling, agriculture and the food sector.

Rate this article

Login to rate this article

Comments

Please login to comment

No comments yet. Be the first to comment!